A gas mask is an element of individual human protection (abbreviation PPE). It counteracts chemical, toxic and dangerous substances. Allows you to operate in extremely polluted environments. Poor performance of one's functions can lead to tragic consequences for a person.

Each manufacturer is required to set a certain expiration date for their products. Since gas masks ensure the health of people in a contaminated environment, the quality of this product must meet all standards.

How long can be stored in the warehouse?

In a warehouse, a gas mask can be stored for up to 10 years; it is only important to comply with the required conditions.

After a control check, the shelf life can be extended for a period of up to 2.5 years.

Filtering

Such PPE has different markings , in particular, GP is the abbreviation for “civilian gas mask”, GP-VM is the same for senior command personnel, PDF-D is a children’s filtering gas mask, D is for children of preschool age, and the presence of the letter “sh” allows you to immediately understand that this PPE is for school-age children.

GP-5, when stored in a new form, without use, can be kept for 3-5 years, and if used, then 2 years.

GP-7, GP-7VM are considered reliable models; the manufacturer guarantees a shelf life of 12 years. The manufacturer allows PDF-2D (w) to be stored for 10 years.

Almost all of these models are subject to extended shelf life after proper inspection.

There are parts in a gas mask that wear out the fastest - this is the box with the filter powder, the filters themselves and the film.

When replacing them, you can continue to use these PPE, but only if the rubber itself is not punctured .

Insulating

The abbreviation IP stands for “insulating gas mask.” The IP-4M brand (without cartridge) has a shelf life of 5 years, the regenerative cartridge RP-7 itself has a shelf life of 7 years. If the cartridge is mounted in a gas mask, then all this together is suitable for 12 months.

The presence of the letter “K” in the name of the IP-4MK brand indicates that the gas mask is equipped with a cartridge; otherwise, these PPE are identical .

The regenerative cartridge RP-6, supplied separately, is suitable for IP-6. Without a cartridge, IP-6 is stored for 5 years, the cartridge itself is stored for 7 years.

Gas mask GP-7B.

- Article: GP-7B-03.2017

- Manufacturer: RUSSIA

1. General requirements

Civilian gas masks (hereinafter referred to as gas masks) are used to protect the respiratory organs, eyes and facial skin of the civilian adult population, including personnel of non-standard emergency rescue units, non-standard units to ensure the implementation of civil defense measures and emergency rescue units.

2. Technical requirements

A civilian gas mask provides protection for the respiratory organs, eyes and skin of a person’s face, without the use of additional cartridges, from:

- organic vapors and gases (test substance – cyclohexane), including low-boiling, poorly absorbed organic substances (test substances – isobutane and dimethyl ether);

- inorganic gases and vapors (except for carbon monoxide) (test substances – chlorine and hydrogen sulfide);

- acid gases and vapors (test substance – sulfur dioxide);

- ammonia and its derivatives;

- chemical warfare agents (including general poisonous action, blister action, organophosphorus compounds - OCP), such as cyanogen chloride, hydrocyanic acid, mustard gas, sarin, soman;

- radioactive substances, aerosols (dust, smoke, fog).

A civilian gas mask provides the ability to receive and transmit sound information by voice and using technical means, as well as ease of putting on the injured person.

The civil gas mask includes:

- front part – 1 piece;

- combined special filter (FKS) – 1 piece;

- anti-fog agent for spectacle glasses – 1 set;

- bag for carrying and storing a civilian gas mask – 1 piece;

- instruction manual – 1 piece per 1 package;

- passport for the product – 1 piece per batch.

Main technical characteristics of a civilian gas mask:

No.

Indicator name

Indicator value

Standard oil mist aerosol suction coefficient under the front part at an air flow rate of 30 dm 3 /min, %, no more

FKS permeability coefficient for standard oil mist aerosol at an air flow rate of 30 dm 3 /min, %, no more

Content of carbon dioxide in inhaled air, % vol., no more

Initial resistance to constant air flow during inspiration

at an air flow of 30 dm 3 /min, Pa, no more:

- combined special filter

- front part

Time of protective action of FKS, at exposure concentrations (Co)

substances (mg/dm 3 ), min, not less:

Vapor permeability coefficient

radioactive iodine-131,%, no more

Field of view area, %, not less

Temperature range of use, °C

Weight of civil gas mask (assembled, without bag), g, no more

FKS mass, g, no more

3. Design requirements

The front part of a civilian gas mask consists of a front part body (a volumetric type mask) with an “independent” seal molded integrally with the mask body, a spectacle assembly with trapezoidal-shaped glasses, an intercom, inhalation and exhalation valve assemblies, a fairing, and a headband. has a five-point connection with the headband straps. The facepiece is equipped with self-tightening straps that make it easy to put on and take off and does not require removal of the facepiece to adjust the headband. The front part is packed in a plastic bag to provide additional protection during long-term storage.

The front parts of civilian gas masks are placed in each box in the following size range: 1 size – 4 pieces; 2 height – 8 pieces; 3 height – 8 pieces.

The body of the filter-absorbing box is made of impact-resistant and heat-resistant polymer composite material, which is not subject to corrosion. The housing material has the property of reversible deformation, which minimizes the likelihood of creating conditions for the penetration of contaminated air along the walls of the housing. FKS is vacuum packed to provide additional protection during long-term storage.

4. Packaging requirements

Civilian gas masks must be supplied in the manufacturer's packaging (wooden boxes, 20 civilian gas masks in each). Each container (box) contains a packing list and an instruction manual for the civilian gas mask.

5. Warranty requirement

The guaranteed shelf life of civilian gas masks is 12.5 years from the date of manufacture, with the exception of anti-fog films – 7.5 years.

6 . Requirements for accompanying documentation

The supplied civilian gas masks are accompanied by a batch passport (original or certified copy) with the seal of the technical control department of the manufacturer, as well as a certified copy of the certificate of conformity of the ACC EMERCOM voluntary certification system.

Mask BR

IZ-4303 (BRIZ-4304)

- increases the convenience and reliability of protection during use;

- has an enlarged more than 70% field of view area

- allows you to mount the box both on the right and on the left;

- the original design of the headband locks allows you to easily adjust the length of the straps when adjusting the mask

- number of Rostov-3.

Operating period

The service life of a gas mask is related to the shelf life of components and spare parts .

If such PPE was issued for use as a duty item, in case of urgent need, then after 2 years they all need to be written off, since no one will guarantee that they are fit to continue to fulfill their mission.

Such emergency kits must be available at every plant in the gas rescue service, as well as in housing and communal services, for carrying out emergency work in wells, etc.

What does it depend on?

The period of operation depends on many factors , including:

- storage conditions;

- time elapsed since release;

- operating conditions;

- Is this device on an extended period, etc.

There is a special approach to this PPE; a damaged gas mask threatens the user with loss of health and poses a threat to life, therefore even a relatively new, but unusable device should be taken out of service.

How much is it?

Devices with filter elements can be used for 2 years, and with a closed breathing system - no more than 1.5 years. After this period, it is recommended to remove the devices from use and write them off as scrap .

Read about the expiration date and storage rules for rechargeable batteries here.

Expiration date of components

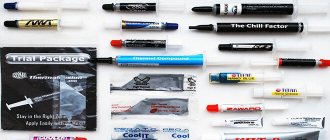

The main replaceable element of gas masks is boxes, which are of two types - filtering and filtering-absorbing; for quick recognition, they are available in different colors .

Each box is marked with the release date, batch number and index of the gas mask for which it is suitable. There are only 6 numbers:

- the first two are the month of release;

- the next two are the year of manufacture;

- the last two are the batch number.

The filter fails faster if it is used frequently , with a high level of pollution, and also with high humidity.

The box is changed if it is difficult to breathe, the smell of gas, dust, etc. appears in the mask. An increase in the mass of the box indicates that the powder has absorbed moisture and has become unusable .

Design and principle of operation

Gas mask filters are enclosed in a durable metal or polymer-composite shell of a cylindrical shape.

The main elements of the device and the composition of the filter for a gas mask are as follows: an anti-aerosol filter and a charge (absorbent filler).

The anti-aerosol filter for a gas mask consists of a special multicomponent material with a frame made of cellulose fibers and the filtering component itself, represented by asbestos fibers, glass fibers and synthetic fibers.

Aerosols are deposited on the fibers due to adhesion (sticking).

Electrically charged materials for filters have also been developed , which capture particles suspended in the air due to electrostatic forces. Air purification from dust particles larger than the filter cell size occurs mechanically, using the sieve principle.

Activated carbon is used in gas masks with absorbent charge filler; it is intended to enhance the filtering effect of the device. The charge is an absorbent layer consisting of activated carbon with additives that specifically enhance the deposition of certain substances in it. Typically, such additives are oxides and salts of various metals, which are located in the pores of the carbon layer.

Storage rules

How to properly store a gas mask and accessories? Gas masks should be kept in cool rooms , during operation - placed in a special bag and in full readiness for use.

It is unacceptable for such PPE to be impersonal: selected in size for each user, they must be labeled, with tags indicating the name and department.

The main enemy of filters is moisture, so controlling the humidity in the room where the spare boxes are located is the most important condition for safety.

How to store a GP5 gas mask? Find out from the video:

How to understand that cement has expired? Find out the answer right now.

Main conclusions

So, let’s draw a line and define the basic storage and care of PPE, which includes basic procedures:

- storage;

- wash;

- drying

- repair.

These events are organized either on our own, having properly organized the process, or under a concluded agreement with an organization that provides these services.

In order for personal protective equipment to serve the employee for a long time and faithfully, and for the employer to reduce its costs for personal protective equipment, you need to:

- dry PPE;

- regularly clean from dirt;

- Do not store near the battery or in direct sunlight.

There are a lot of details about the storage and care of PPE, so study order No. 290n, POT and work safely and efficiently!

If you have something to add or have examples from practice, write comments, it will be discussed, this is important for other readers.

Reasons for write-off

A gas mask is considered unusable and must be written off if:

- the mask has cuts, punctures or other damage;

- hoses (if any), tubes are damaged;

- traces of rust appeared on metal parts;

- the planes of parts of the respiratory system are deformed, etc.

If the box with the filter or absorber is bent, pierced, when powder spills out or the smell of gas is heard, then such spare parts are unusable and should be written off .

Filter boxes saturated with moisture become heavy, and simple weighing can provide grounds for discarding a damp filter.