cylinder passport

- the mark of the certifying organization (certification may be located in different places), the frequency of re-examination is once every 5 years.

- month, year of the certification passed and the year until which the certification is valid.

- manufacturer's mark.

- serial number of the cylinder.

- month of manufacture, year of manufacture, certification of the manufacturer.

- working pressure of the cylinder.

- cylinder test pressure.

- cylinder volume.

- Quality Control Department stamp of the manufacturer.

- cylinder weight.

Effect of pepper spray

Well, now let’s find out how the pepper spray works. Extracting hot pepper provokes severe irritation of the mucous membranes. In a mild case, the attacker begins to cough violently.

If the moment of splashing coincides with a deep breath, then pulmonary edema cannot be ruled out, and, if you are prone to allergies, the victim may suffocate. If an asthmatic is exposed to pepper extract, death is also possible. Similar cases have been described in judicial practice.

If a cloud or stream of pepper spray gets into your eyes, the consequences are also very unpleasant.

In addition to profuse lacrimation, blepharospasm occurs. The muscle in one or both eyes begins to contract uncontrollably, preventing the eyes from opening. It will take time for the attacker to blink, which means you have the opportunity to escape.

If the canister accidentally fell into the hands of children or you were exposed to hot pepper yourself, you should know the rules of first aid or self-help. If possible, you should see an ophthalmologist after the incident.

What factors affect shelf life?

The manufacturer sets the operating period of the gas cylinder. If this characteristic is absent, it is equivalent to 20 years. There are factors that, with a pronounced influence, can change it:

- what the container is made of;

- when was it produced;

- how it is used.

With proper use, they serve the standard period without problems. It is also important to carry out inspections in a timely manner. If storage and use conditions are not met, they will become unusable sooner.

Marking

This is a description of all the characteristics of the cylinder and its contents. The main thing is to read the symbols correctly: the markings can give a complete description of any gas container. For different types, information has an individual location.

ADVICE! The shelf life is easy to calculate, knowing the established period for a given type of container and gas and the production date.

Methane

They are painted with red paint, the inscription is white. The difference from propane is the absence of a weld. The marking on the valve contains the following information:

- working pressure (MPa);

- test pressure (MPa);

- volume (l);

- factory number;

- date of. This characteristic is especially important, since the first four digits indicate the month and year of manufacture, and the last two indicate the next certification;

- empty and full weight (kg);

- certification data: stamp of the competent organization, last year it was valid.

Propane

Red paint with white lettering is used.

On them, information is printed on the valve, or rather, on its metal circle. It says:

- working pressure (MPa);

- test pressure (MPa);

- volume (liter);

- factory number;

- date of. This characteristic is especially important, since the first four digits indicate the month and year of manufacture, and the last two indicate the next certification;

- empty and full weight (kg);

- certification data: stamp of the competent organization, last year it was valid.

The suitability of a vessel can only be judged after careful study of all the information. If any data is unclear, the inscription is mechanically damaged, the container must be removed and sent for repair.

Oxygen

Painted blue, lettering black.

They have their own special designations:

- information about the manufacturer and container number;

- date of production and future inspection;

- pressure: working and hydraulic;

- volume of gas, weight of the container without valve and cap.

For durability, the information is not applied with paint, but is embossed and coated with a special varnish: it will protect against corrosion.

How to install a propane tank

Propane cylinders are permitted to be installed both outside and inside the building, where they can be easily inspected or replaced.

If there are heating radiators or stoves nearby, then propane tanks should be located approximately 1.5 meters from them.

Outside buildings, propane tanks are placed in a special locked cabinet or enclosure that covers the top of the tank and the pressure regulator.

The distance from propane cylinders to doors and windows should be more than 0.5 meters, and in basements and on ground floors - 3 meters.

The process of inspection and restoration of containers for industrial gases

Regulatory documentation, namely the “Rules for the Arrangement and Operation of Vessels...” stipulates the regularity of inspection of the technical condition of gas vessels.

Rules for using acetylene cylinders

For example, inspection of acetylene cylinders is carried out once every five years. While the mass inside the cylinder must be checked at least once every 2 years. By the way, on the cylinder there must be a mark indicating the timing of the inspection, the result of the inspection of the porous mass, and the timing of the next inspection of the cylinder.

In accordance with the technical conditions, only those containers that have passed all the necessary tests and all relevant records have been made are allowed for operation. New vessels undergo the necessary test cycle during product acceptance by the technical control service.

After the expiration of the inspection period, the cylinders must undergo re-examination, that is, a full inspection of the technical condition. At the same time, those that have not passed the re-examination must be withdrawn from circulation and sent for recycling (disposal).

Tanks on which correctable defects are found are subject to repair and, after completing the required work and conducting proper tests, can be returned to operation.

How to eliminate the consequences

If you are caught in a stream or cloud, it is advisable to quickly eliminate the consequences of pepper spray. The algorithm of actions in this case is not very complicated:

- Do not rub your eyes, even if they are very hot and watery.

- Blink frequently so that the tears wash away the pepper extract.

- Gently pat your eyes dry with a damp, alcohol-free tissue.

- Rinse your eyes with full-fat milk, then with a soda solution. Concentration – 20 g per 1 liter of water.

In the future, try to be more careful when using pepper spray. You now understand how to get rid of the consequences yourself. The ophthalmologist will then assess the extent of the damage and recommend eye drops.

Most often this is the banal “Albucid” or painkillers and anti-inflammatory drops with diclofenac. If the burning sensation is severe, lidocaine drops may be recommended, but they must be used strictly according to the instructions so that visual acuity does not decrease. You can only use Visine on your own, but this remedy eliminates redness rather than helps overcome the consequences of contact with pepper extract.

If you are allergic or asthmatic, also see a doctor to avoid serious consequences from exposure to pepper spray.

Types of repairs

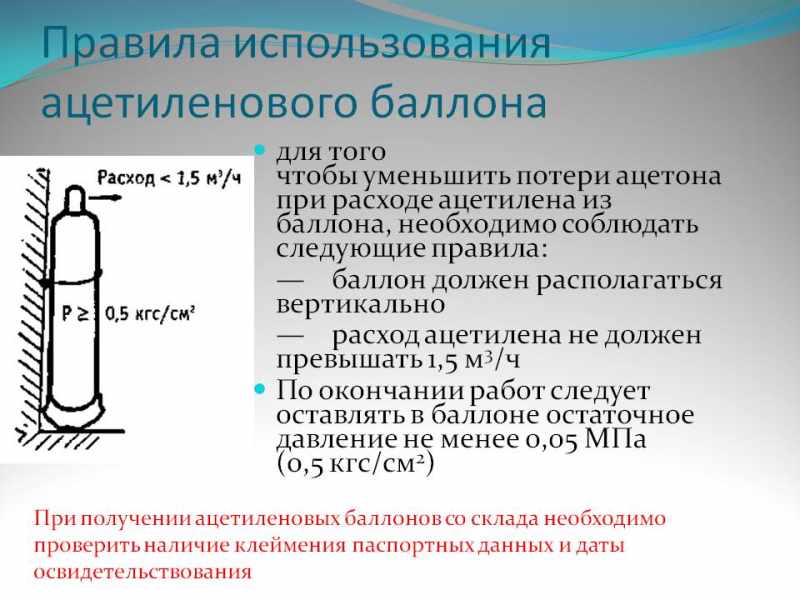

You can understand that the cylinder requires repair by the following signs:

- the valve is faulty, there are cracks in the pressure gauge;

- damaged, dislodged shoe;

- the neck thread is worn or faulty;

- the seal is broken;

- color mismatch.

Such containers must be urgently delivered to a specialized organization for troubleshooting.

If gross violations are discovered during the repair, it will be sent for disposal:

- significant external damage: dents, corrosion, cracks;

- absence or unclearness of the passport, markings;

- cracks on the weld a third of the length.

An experienced technician will solve the remaining problems. Independent attempts to repair vessels are prohibited.

Certification verification and re-examination

Vessels must meet certain requirements so as not to threaten the life and health of people. To do this, it is necessary to provide containers with timely verification or inspection.

IMPORTANT! Organizations that hold a license and permit from Rostechnadzor have the right to carry out such specific activities.

The timing of cylinder performance checks depends on the material, contents, and operating conditions. Can be 2, 5 or 10 years.

The procedure involves several stages:

- Receiving containers for research. The specialist checks the completeness, the date of the last inspection, and performs an external inspection.

- Using special devices, the interior is inspected and the fittings are removed.

- Pressure resistance test. This is the most important stage that will identify defects and potential risks.

- If everything is in order, the product is dried and the fittings are replaced.

- Finishing is sandblasting and painting with paint of a special consistency, it protects against corrosion.

- Marking.

- Drawing up an act.

Passport

This is the main document containing important information about the production and maintenance of the cylinder. You can find out information:

- certification data: date and last year of validity;

- manufacturer's mark;

- serial number;

- Date of issue;

- operating pressure;

- test pressure;

- volume;

- weight.

Until December 19, 2014, the passport was applied directly to the neck of the container. The document was a quality certificate for a batch of goods, where the register contained the number of a specific product.

After this date, the legislator obliged manufacturers to provide all vessels with a passport. Now the listed information is attached to each container without fail.

Rules to remember

To effectively protect yourself with pepper spray, you need to remember a few rules that will help in dangerous situations.

Firstly, you need to know how to use a spray can. The first time, it’s worth buying two pieces so that you can train on one and use the other for self-defense.

Secondly, the can must have a specific storage location. This is very important because you won't have time to search. Before a dangerous section of the path, it is generally worth taking it in your hand.

Keeping pepper spray in a woman's purse is a futile exercise. In an emergency, there is simply no time to unzip and find a means of self-defense in the depths of your trunk. The attacker will have time to strike first.

Thirdly, after using pepper spray, you need to be prepared for two options for the development of the situation. You will either have to engage in a fight with a weakened enemy, or quickly run away.

Well, in winter, if you overcool (freeze) the pepper spray, the consequences can be quite sad. The effectiveness of the application will be significantly reduced: instead of temporarily neutralizing the attacker, you will simply anger him.

Content Spray Options

Pepper sprays are produced with different types of spray:

- Jet version, that is, a directed jet with a long range of influence. This option is suitable for people with good marksmanship, but makes self-defense difficult if there are several attackers.

- Aerosol version, that is, spraying occurs in a cloud, causing a larger affected area. When using this option in enclosed spaces, certain difficulties may arise, since it is easy to get caught in a cloud of pepper.

Replacement Precautions

Replacing the valve on a gas cylinder must be carried out in compliance with certain safety measures, including the following:

Replacing the gas cylinder valve

- Remove any remaining gas from the vessel. It is permissible to release gas only in an open space. An exception can be made only for nitrogen, oxygen and a number of others.

- The workplace where work will be performed must be well ventilated.

- The flywheel must be unscrewed smoothly and at low speed.

- The valve can be replaced only after equalizing the pressure outside and in the cylinder.

When installing the valve in its original place in the cylinder, it is necessary to use fum tape and other types of sealants that ensure a reliable connection. It should be noted that seals of any type can create certain difficulties when removing the valve. To make this task easier, it is permissible to use a hair dryer.

It is permissible to heat the fittings installed on the cylinder only after emptying the contents of the container.

When no longer suitable

After the expiration of the standard service life, the containers are disposed of. It is prohibited to accept them for refueling, despite their external integrity. Such stringent measures are aimed at protecting the user: material that has served the allotted time will begin to deteriorate at any moment, and over-limit operation is dangerous.

In addition, with the above-mentioned serious malfunctions, it is also impossible to continue using the vessel.

Dear readers! To solve your problem right now, get a free consultation

— contact the lawyer on duty in the online chat on the right or call: +7 (499) 938 6124 — Moscow and region.

+7 (812) 425 6761 — St. Petersburg and region. 8 (800) 350 8362 - Other regions of the Russian Federation You will not need to waste your time and nerves - an experienced lawyer will solve all your problems! Or describe the situation in the form below: